Pilot and Historical Projects

Imani Vocational Training is dedicated to innovation. The school and its leadership are constantly looking for new opportunities to improve the quality of life and learning provided to its students. By first implementing a small-scale version of a project, Imani is able to determine whether or not the project could feasibly and profitably rolled out on a larger scale. Many of Imani's established food- and income-generating activities were initially implemented as experimental pilot projects.

By constantly experimenting with new techniques and ideas--and eagerly sharing its lessons learned with the community--the school is able to contribute indirectly to economic development in the surrounding local areas. Below you will find a profile of some ongoing and historical pilot projects at Imani.

Black Soldier Fly Larvae Compost

With a large student body and a wide variety of ongoing agricultural initiatives, the school generates a large volume of organic matter that can be used as compost to improve its overall output and efficiency. The school has partnered with the University of Sherbrooke to improve its composting techniques and develop resources to share best practices.

The latest initiative involves the use of black soldier fly larvae in composting. The larvae consume great amounts of organic waste and convert it into edible insect protein that can be fed to the pigs or chickens. A video overview of the process was recently developed by the Sherbrooke students.

Rocket Stoves

Tanzania has a population of roughly 35 million people living in a territory roughly the size of Ontario. It has a hot and dry climate for much of the year, a limited electrical grid (about 14% of Tanzanians have access), a developing economy, and a population that primarily uses wood or charcoal for cooking. The result is a general shortage of wood for the average Tanzanian, who either buys or scrounges wood fuel for cooking.

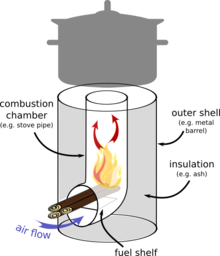

Rocket stoves help reduce the amount of wood required for cooking. An insulated metal tank and an internal convection system result in less energy wasted when cooking. The cost and time savings to an organization or individual can be immediate and significant.

Fish Ponds

Between 2008 and 2012, the school built and operated two fish ponds on its property. Essentially a 1-meter deep hole in the ground, the ponds were filled with water and small tilapia fish purchased a from a supplier. Fed using a variety of waste products from its other projects (eg. corn shells, food scraps), the fish grew and reproduced rapidly. Harvests were plentiful, yielding hundreds of fish every few months.

Ultimately the fish ponds were discontinued despite their high level of productivity. Over time it became difficult to maintain the appropriate chemical balances required for healthy fish. With a higher level of expert knowledge and advice, the fish pond project might one day be revisited. Although the fish ponds did not succeed in the long run, the financial investment to develop them (about $1000 each) was easily offset by a number of successful harvest cycles.